Efficient manufacturing processes are the backbone of modern industry. Precise instruments like the vacuum pressure gauge are essential for maintaining this efficiency, ensuring optimal performance, and reducing waste. In this article, we explore how various tools and strategies can enhance efficiency in manufacturing environments.

Importance of Efficiency in Manufacturing

Efficiency in manufacturing is crucial for reducing costs, increasing output, and maintaining competitiveness. High efficiency means less waste, lower energy consumption, and more reliable production schedules. This is especially important in a global market where margins can be slim and competition fierce.

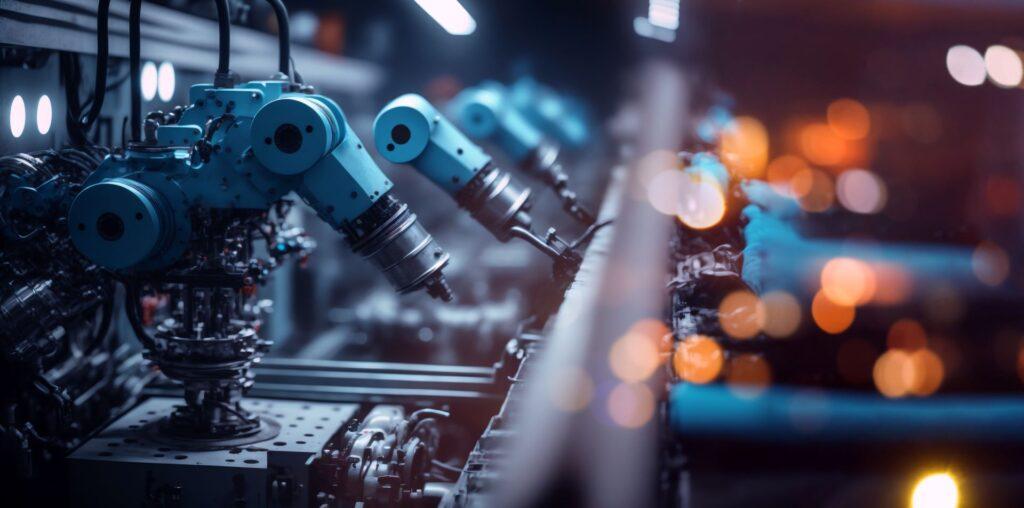

To achieve these goals, manufacturers must continuously optimize their processes. This involves regular assessments and the adoption of advanced tools and technologies that can streamline operations. For instance, automated systems can significantly reduce human error and increase the speed of production lines, while precision instruments like vacuum pressure gauges ensure that machinery operates within the optimal parameters.

Moreover, efficiency in manufacturing directly impacts product quality. Consistent processes lead to consistent products, which is essential for maintaining brand reputation and customer satisfaction. Investing in efficiency is not just about cutting costs; it’s about building a sustainable and resilient manufacturing operation.

Key Tools for Measuring and Ensuring Efficiency

Several tools are pivotal in measuring and ensuring efficiency in manufacturing processes. Among these, vacuum pressure gauges are indispensable. They help monitor and control the pressure in various manufacturing processes, ensuring that machinery operates efficiently and safely.

Other essential tools include:

- Thermocouples and temperature sensors: These devices measure temperature accurately, ensuring that processes involving heat are controlled precisely.

- Flow meters: These instruments measure the flow rate of liquids and gases, crucial for maintaining consistent production conditions.

- Automated control systems: These systems integrate various sensors and control mechanisms to automate production processes, reducing human error and increasing efficiency.

Each of these tools plays a specific role in maintaining efficiency. For example, vacuum pressure gauges are critical in processes that require precise pressure control, such as in the production of semiconductors or pharmaceuticals. By maintaining the correct pressure, these gauges prevent equipment damage and ensure product quality.

Implementing these tools requires careful planning and integration into existing systems. Manufacturers must consider the specific needs of their processes and choose the right instruments to meet those needs. Regular calibration and maintenance of these tools are also essential to ensure their accuracy and reliability.

Role of Vacuum Pressure Gauges in Manufacturing

Vacuum pressure gauges are used in a variety of manufacturing processes where precise pressure control is essential. They measure the pressure in a vacuum system, ensuring that it stays within the required parameters. This is crucial in processes like vacuum packaging, semiconductor manufacturing, and chemical processing.

In vacuum packaging, for instance, maintaining the correct vacuum pressure ensures that products are sealed properly, extending their shelf life and preserving quality. In semiconductor manufacturing, precise pressure control is essential for creating the right environment for producing high-quality chips.

The benefits of using vacuum pressure gauges include:

- Enhanced safety: By monitoring pressure levels, these gauges help prevent equipment failures that could lead to accidents.

- Improved product quality: Consistent pressure levels ensure that manufacturing processes produce high-quality products.

- Reduced downtime: Accurate pressure monitoring can identify potential issues before they cause significant problems, reducing unplanned downtime.

Manufacturers can integrate vacuum pressure gauges into their automated systems to provide continuous monitoring and control. This integration allows for real-time adjustments, ensuring that processes remain efficient and effective.

Narratives from Manufacturing Plants That Have Improved Efficiency

Electronics Manufacturer Enhances Production Line

A major electronics manufacturer faced challenges with maintaining the efficiency and quality of their production line due to inconsistent vacuum levels in their soldering process. They integrated vacuum pressure gauges into their vacuum soldering systems to monitor and control the vacuum levels precisely.

Key Outcomes:

- 20% increase in production efficiency: The precise control of vacuum levels reduced errors and rework, speeding up the production process.

- 15% reduction in defective products: Consistent vacuum levels ensured better quality soldering, leading to fewer defects.

- Significant cost savings: Improved efficiency and reduced waste translated into substantial cost savings for the company.

By leveraging the accuracy of vacuum pressure gauges, the manufacturer was able to streamline their production processes and achieve higher product quality.

Pharmaceutical Company Streamlines Sterilization Process

A pharmaceutical company needed to ensure the sterility of their products, which involved using vacuum chambers for sterilization. They encountered issues with maintaining the required vacuum levels, leading to inefficiencies and potential contamination risks. Implementing advanced vacuum pressure gauges provided real-time monitoring and control over the vacuum levels.

Key Outcomes:

- 30% increase in process efficiency: Real-time monitoring reduced the time needed to achieve and maintain the necessary vacuum levels.

- Enhanced product safety: Accurate vacuum control minimized the risk of contamination, ensuring the safety of pharmaceutical products.

- Operational cost reduction: The company saved on operational costs due to increased efficiency and reduced downtime.

This success story demonstrates how vacuum pressure gauges can significantly improve critical processes in the pharmaceutical industry, ensuring both efficiency and safety.

… they will offer even greater opportunities for improving efficiency and productivity in manufacturing processes.

Future Trends in Manufacturing Technology

The future of manufacturing technology is set to be shaped by advancements in automation, artificial intelligence, and precision instrumentation. As these technologies continue to evolve, they will offer even greater opportunities for improving efficiency and productivity in manufacturing processes.

Automation will become increasingly sophisticated, with machines capable of performing more complex tasks with minimal human intervention. Artificial intelligence will enhance decision-making processes, allowing manufacturers to optimize their operations in real-time. Precision instruments like vacuum pressure gauges will continue to play a crucial role in maintaining the accuracy and reliability of manufacturing processes.

Additionally, the integration of IoT (Internet of Things) technology will enable greater connectivity and data sharing across manufacturing systems. This connectivity will allow for more comprehensive monitoring and control, leading to further improvements in efficiency and productivity.

The Road to Manufacturing Excellence

Enhancing efficiency in manufacturing is an ongoing process that requires continuous investment in advanced tools and technologies. Precision instruments like a vacuum pressure gauge are essential for maintaining optimal performance and ensuring product quality. By adopting these technologies and staying abreast of future trends, manufacturers can build resilient, efficient, and competitive operations. This commitment to efficiency not only benefits the bottom line but also supports sustainable and innovative manufacturing practices for the future.

Picture Credits:

Adin – stock.adobe.com

Sergey Ryzhov – stock.adobe.com